In the global of present-day manufacturing, the introduction of tricky and reliable components has been revolutionized through the technique of injection molding. This innovative manufacturing approach has redefined how we produce everything from normal household objects to complex industrial equipment.

Kemal Manufacturing, a pioneer in precision manufacturing, presents a prime example of the way this technique can be harnessed to create great injection molded parts. In this article, we can explore the tricky world of injection molding and its packages, with a focal point on Kemal production’s knowledge on this subject.

Understanding Injection Molding

Injection molding is a fairly flexible production procedure used to create a wide variety of plastic and metal components. The manner includes injecting molten material into a mold hollow space, wherein it cools and hardens to form the preferred shape. It’s an especially efficient approach for generating complicated, high-precision components at scale, and it has grown to be a vital part of contemporary production throughout numerous industries.

Explore Injection Molding Processes

Kemal production’s expertise in injection molding is evident via its comprehensive abilities and commitment to delivering super-precision additives. Permits delve into the injection molding processes highlighted on their website:

Material Selection:

The injection molding method started to evolve with the cautious selection of the cloth for use. Kemal manufacturing offers a wide variety of fabric options, such as thermoplastics and thermosetting plastics, as well as metals. The choice of material relies upon at the specific necessities of the challenge, thinking of elements like energy, sturdiness, warmth resistance, and chemical resistance.

Mildew Layout:

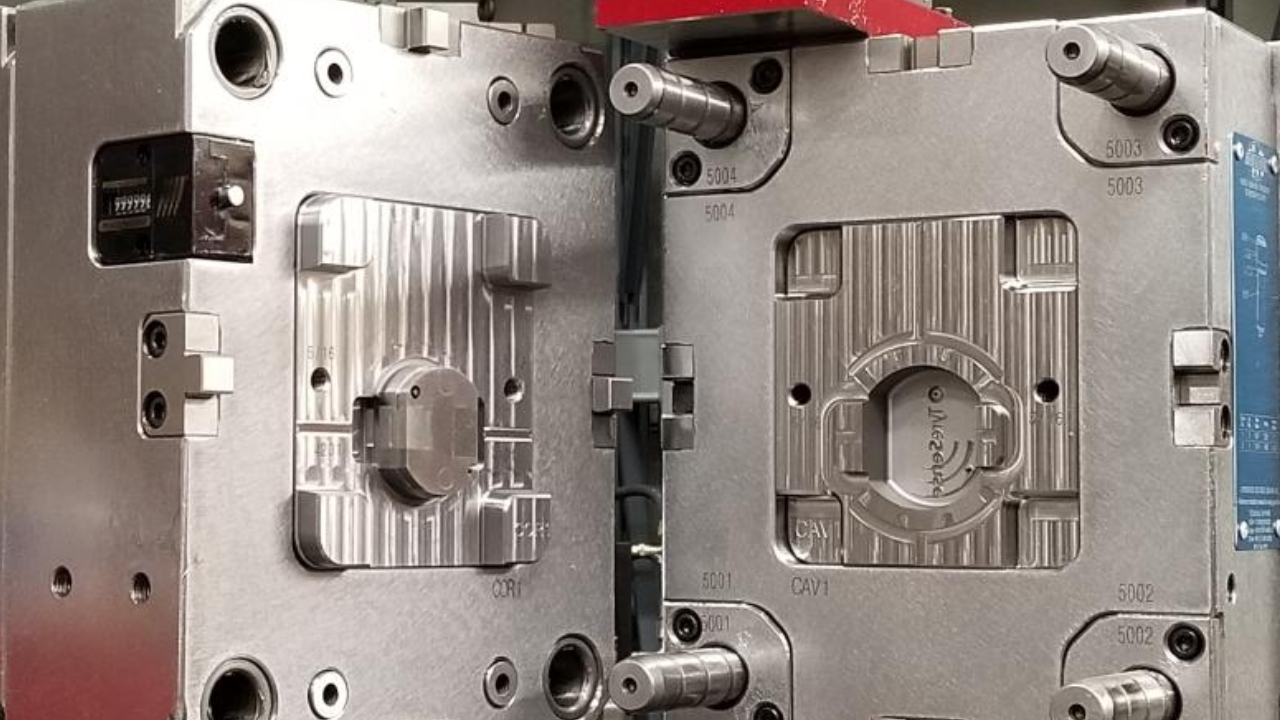

Once the material is chosen, the following step is the design of the mold. Kemal manufacturing utilizes present-day layout software programs and equipment to create molds tailor-made to the patron’s specs. These molds are precision-engineered to make sure the very last additives meet the desired form, size, and first-class standards.

Mold Maundering:

After the layout phase, the actual mildew is manufactured. Kemal production’s cutting-edge facilities are prepared with superior devices to provide molds with excessive precision. The molds are crafted to resist the pressures and temperatures of the injection molding manner, ensuring consistency and reliability at some stage in manufacturing.

Injection molding system:

The coronary heart of injection molding lies in the molding procedure itself. It starts with the injection gadget heating the chosen cloth to a molten nation. The molten fabric is then injected into the mold hollow space below stress, wherein it takes the form of mildew. The cooling section follows, allowing the fabric to solidify and take the preferred form.

Quality Assurance:

The fine is a pinnacle priority for Kemal manufacturing. Their dedication to delivering components that meet genuine specifications is sponsored by way of stringent fine manipulation measures. During and after the molding method, each part is thoroughly inspected to make certain it adheres to the purchaser’s requirements, whether the ones are for the car enterprise, clinical devices, or purchaser items.

Custom Solutions:

One of Kemal production’s standout features is its capacity to offer custom solutions. They excel in creating intricate, excessive-precision additives with tight tolerances. Their know-how extends to the production of complicated, multi-factor assemblies. This customization is a testament to their commitment to tailoring answers to the particular needs of their customers.

Post-Processing:

In lots of instances, submit-processing is required to meet unique project requirements. Kemal manufacturing offers offerings inclusive of meeting, painting, plating, and printing to provide customers with absolutely complete additives prepared for integration into their products or packages.

Scalability:

Kemal manufacturing’s injection molding manner is scalable to deal with numerous undertaking sizes. Whether it’s for fast prototyping or full-scale production runs, their superior equipment and skilled technicians can adapt to fulfill the production volume needs of their customers.

Sustainability:

An important aspect of cutting-edge production is sustainability. Injection molding is an inherently efficient method that generates minimal waste. It is also conducive to recycling and the reduction of strength intake, contributing to greater green manufacturing practices.

Conclusion

Injection molding is a versatile and necessary manufacturing process that reveals applications in infinite industries and products. Kemal production’s mastery of this method, as highlighted on its internet site, demonstrates its dedication to precision and efficiency. Their abilities, attention to exceptional, and potential to provide customized solutions position them at the forefront of injection molding.